Product Description

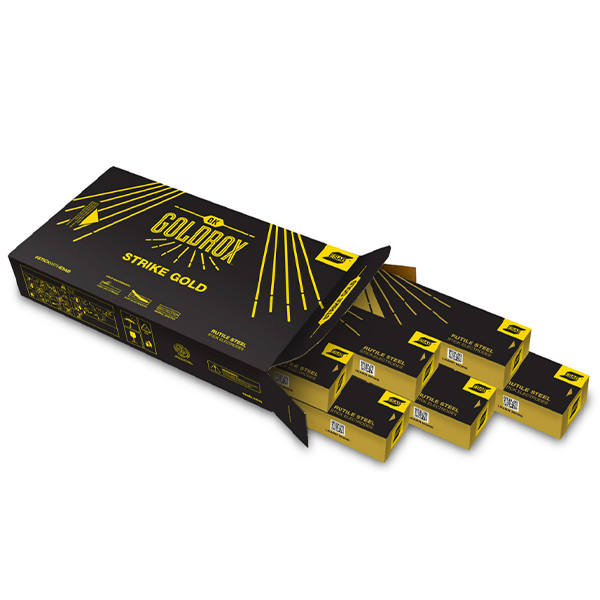

ESAB 83111000 OK GoldRox 2.5x350mm 1KG Rutile Steel Stick Electrodes

Arc Striking, Made Easy.

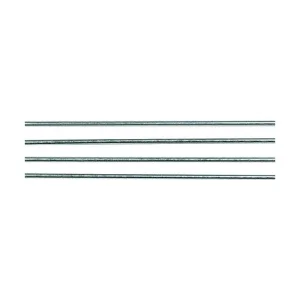

OK GoldRox rutile 6013 electrodes deliver brilliant performance for everyday stick welding applications, with properties that help fabricators – of all skill levels – turn their projects into gold. Arc striking and re-striking are simple, even with low-voltage power sources. You’ll get the top performance you want, so you can weld with a Midas touch.

Kick Annoying Slag Removal to the Curb.

Removing unwanted slag after welding or in between passes is a normally a pain. It takes chipping hammers, wire brushes or wheels, or a needle scaler. With OK GoldRox electrodes, we make slag removal easier with better release and minimal effort. This saves you time and money on the post-weld clean up.

Quality Welds with Minimal Spatter.

Exceptional arc stability is the name of the game with OK GoldRox electrodes. As a result, you’ll reduce spatter dramatically, especially when compared to standard 6013 electrodes, cutting down on cleaning times. Quality welds have minimal spatter – and we make them easy to achieve with OK GoldRox.

Superior Performance in Every Position.

Whether welding flat, horizontal, vertical, or overhead, OK GoldRox electrodes will help you get virtually any job done well. It is the true all-round and all-position rutile electrode. Plus, it features start and restart properties that allow for easy tack welds that novice and experienced welders can rely on.

| Specifications | |

|---|---|

| Classifications | SFA/AWS A5.1 : E6013 EN ISO 2560-A : E 42 0 RC 11 |

| Approvals | ABS : 2 BV : 2 CE : EN 13479 DB : 10.039.48 DNV : 2 LR : 2 UKCA : EN 13479 VdTÜV : 19622 |

| Welding Current | DC+-, AC |

| Alloy Type | Carbon Manganese |

| Coating Type | Rutile-cellulosic covering |

| Condition | Yield Strength | Tensile Strength | Elongation |

|---|---|---|---|

| ISO | |||

| As Welded | 450 MPa | 520 MPa | 26 % |

| Condition | Testing Temperature | Impact Value |

|---|---|---|

| ISO | ||

| As Welded | 0 °C | 60 J |

| Typical Weld Metal Analysis % | ||

|---|---|---|

| C | Mn | Si |

| 0.07 | 0.45 | 0.42 |

| Deposition Data | |||||

|---|---|---|---|---|---|

| Diameter | Current | Voltage | Efficiency (%) | Fusion time per electrode at 90% I max | Deposition Rate |

| 2.0 x 300.0 mm | 50-70 A | 25 V | 60 % | 38 sec | 0.55 kg/h |

| 2.5 x 350.0 mm | 60-90 A | 25 V | 62 % | 49 sec | 0.8 kg/h |

| 3.2 x 350.0 mm | 90-140 A | 24 V | 59 % | 57 sec | 1.1 kg/h |

| 4.0 x 350.0 mm | 110-185 A | 26 V | 58 % | 64 sec | 1.4 kg/h |

Related Products

Best Selling Products

-

Siroflex Contractors Sanitary Silicone – White

£3.58 ex VAT -

A-One Tools & Fixings LMN Clear Silicone

£3.45 ex VAT -

Siroflex Mighty Strength Grip & Grab Adhesive 290ML

£4.95 ex VAT -

Siroflex Contractors Sanitary Silicone – Clear

£3.58 ex VAT -

Bond-It WP70 LMN Oxime Silicone – Buff

£3.36 ex VAT -

Multi-Tak 500ml Aerosol Heavy Duty General & All Purpose Spray Adhesive

£2.99 ex VAT -

A-One Tools & Fixings MS Fix & Seal Durable, Flexible MS Polymer – White

£3.95 ex VAT -

A-One Tools & Fixings Mighty Strength ClearBond MS

£3.95 ex VAT -

Siroflex Premium Building Silicone – Clear

£5.20 ex VAT -

Bio Shield Guard 80 Alcohol Based 400ml Sanitiser Spray

£3.95 ex VAT -

A-One Tools & Fixings UPVC Glass Cleaner 1ltr Bottle

£3.99 ex VAT -

Makita DC18RC 14.4V-18V Li-Ion Single Rapid Charger 240V

£24.99 ex VAT